Successfully sustainable.

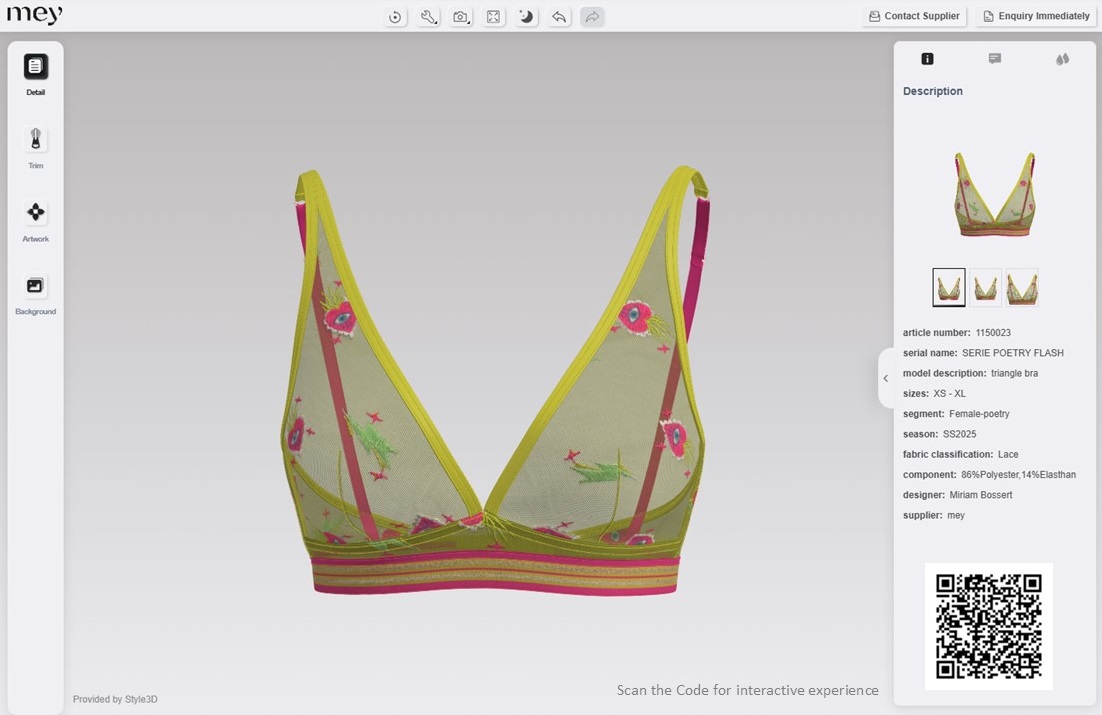

Lingerie and daywear digitally through to production

- Less need for physical samples and materials

- Accelerate iterations during development

- Present collections digitally

- Precisely calculate fabric consumption

About Mey

- 3 production facilities (Germany, Hungary, Poland)

- 1100+ employees

- approx. 50% value creation in Germany

- stores in Germany, France & Austria

- Global distribution

- founded in 1928

mey is one of Europe’s leading brands for high-quality women’s and men’s underwear, lingerie, nightwear, and loungewear. Each product is designed, produced, and marketed with creativity, passion, and an eye for detail. For mey, innovation goes beyond creating something new – it’s about continuously evolving its business, products, and processes. With a significant part of its value creation happening in Germany, mey ensures the highest quality standards are met.

Premium European-Made Apparel

The family-owned company places high importance on sustainable and socially responsible practices, producing almost exclusively in its own facilities across Europe. mey has gained a significant competitive edge through comprehensive digitization across all business areas and was among the pioneers in adopting 3D technology.

Collaboration & Sustainability

At its facilities in the Swabian Alps and across Europe, mey seamlessly integrates tools like Style3D Studio, Style3D Fabric, Style3D Cloud (EU), Assyst.CAD and 3D/2D.Connect. It furthermore connects automated laying and costing (Automarker/Autocost) to its proprietary ERP system. Those implementations are driving measurable success. Over recent years, the company has experienced significant growth, optimized material usage, and adopted an outstanding sustainability strategy.

mey tracks its sustainable fabrics directly from the growing fields to processing in its own facilities. Given that these truly climate-friendly resources are scarce, maximizing material usage is a top priority for mey. With Autocost, the company achieves a significant optimization in the double-digit percentage range.

By using Style3D Studio in combination with AI, the company aims to develop even more sustainably. Physical samples for many products will then be completely eliminated.