Assyst.Automarker

Structured Marker Making & Efficient Nesting

Lay markers automatically, meet your quality goals, and connect directly with your production partners worldwide. Try highly efficient nesting!

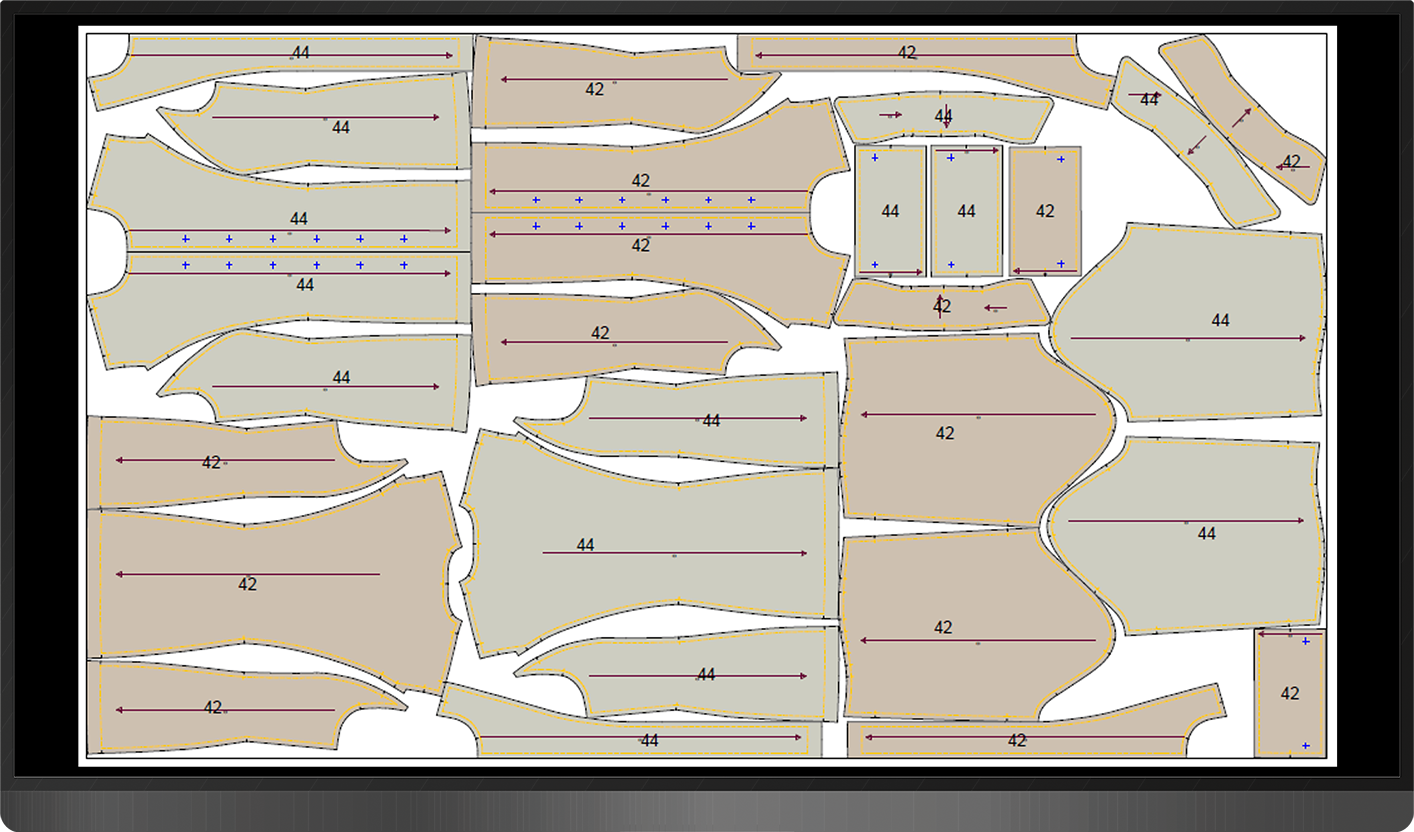

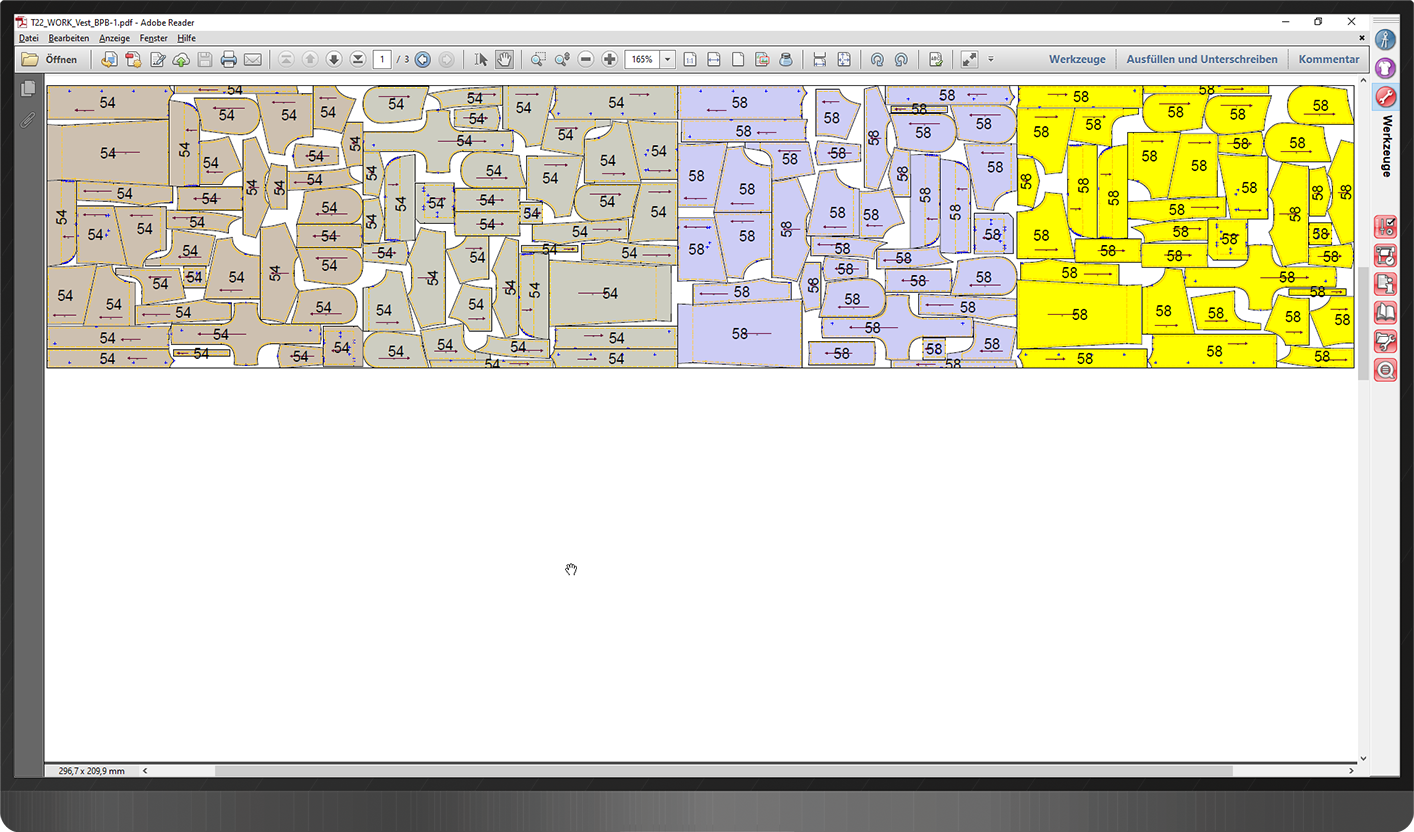

Saving fabric and protecting the environment

Automarker automatically generates high-quality markers across the entire collection cycle, saving time, material, and costs while reducing your carbon footprint. With customizable laying rules, you ensure quality standards and sustainably secure your expert know-how.

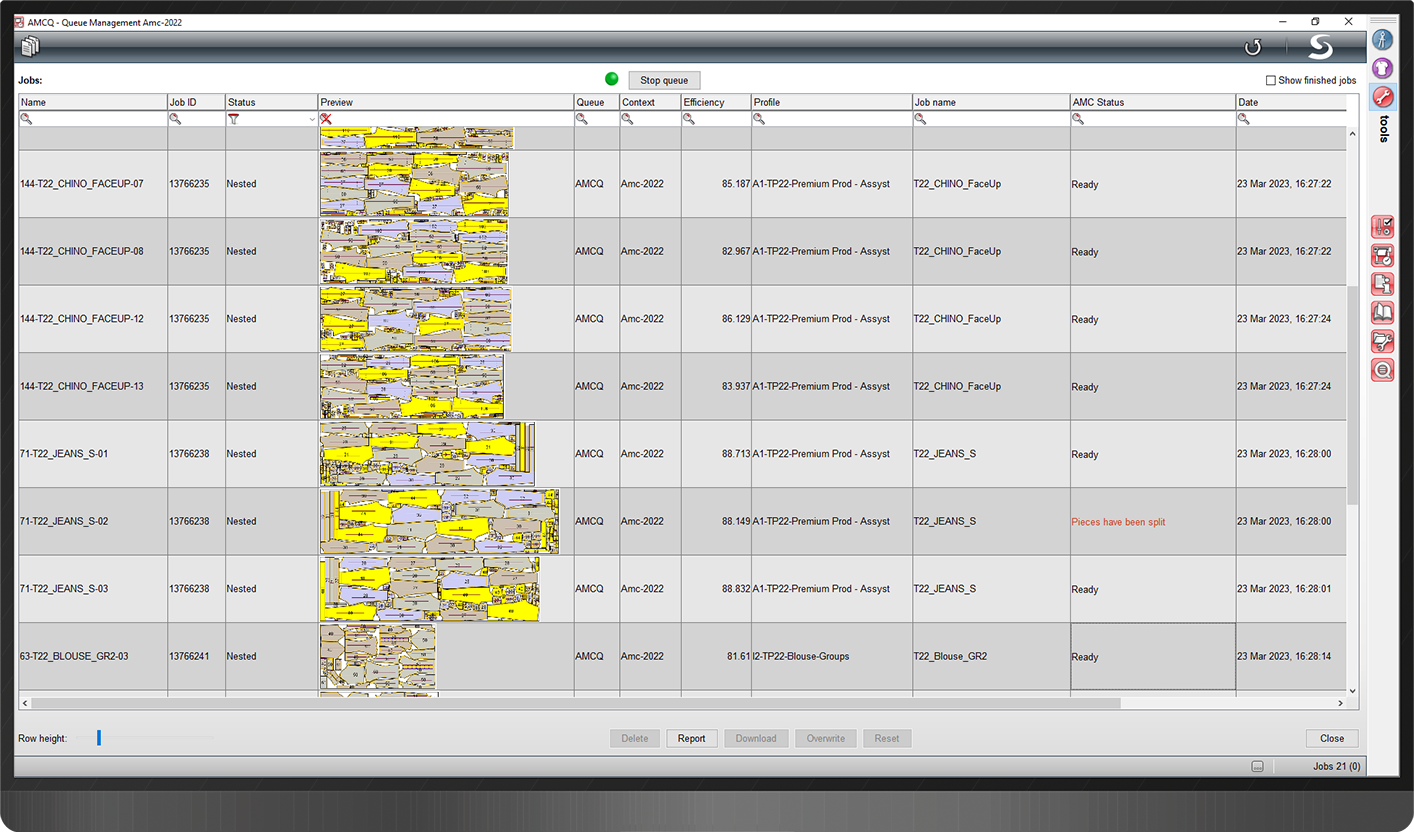

Balancing peak loads and saving time

Instead of manually laying out one marker at a time, with Automarker, you can lay out all orders in parallel in the shortest possible time and directly pass them to the production partner. This ensures smooth processes, saves time, and helps to mitigate peak loads.

Connecting suppliers and automatically avoiding errors

All orders are transferred in the correct format, regardless of the CAD system. Simply output the data in the required plot or cutfile format, select the production partner, and transmit the order.

Automated nesting in the cloud

always on, efficient and adopted to your needs

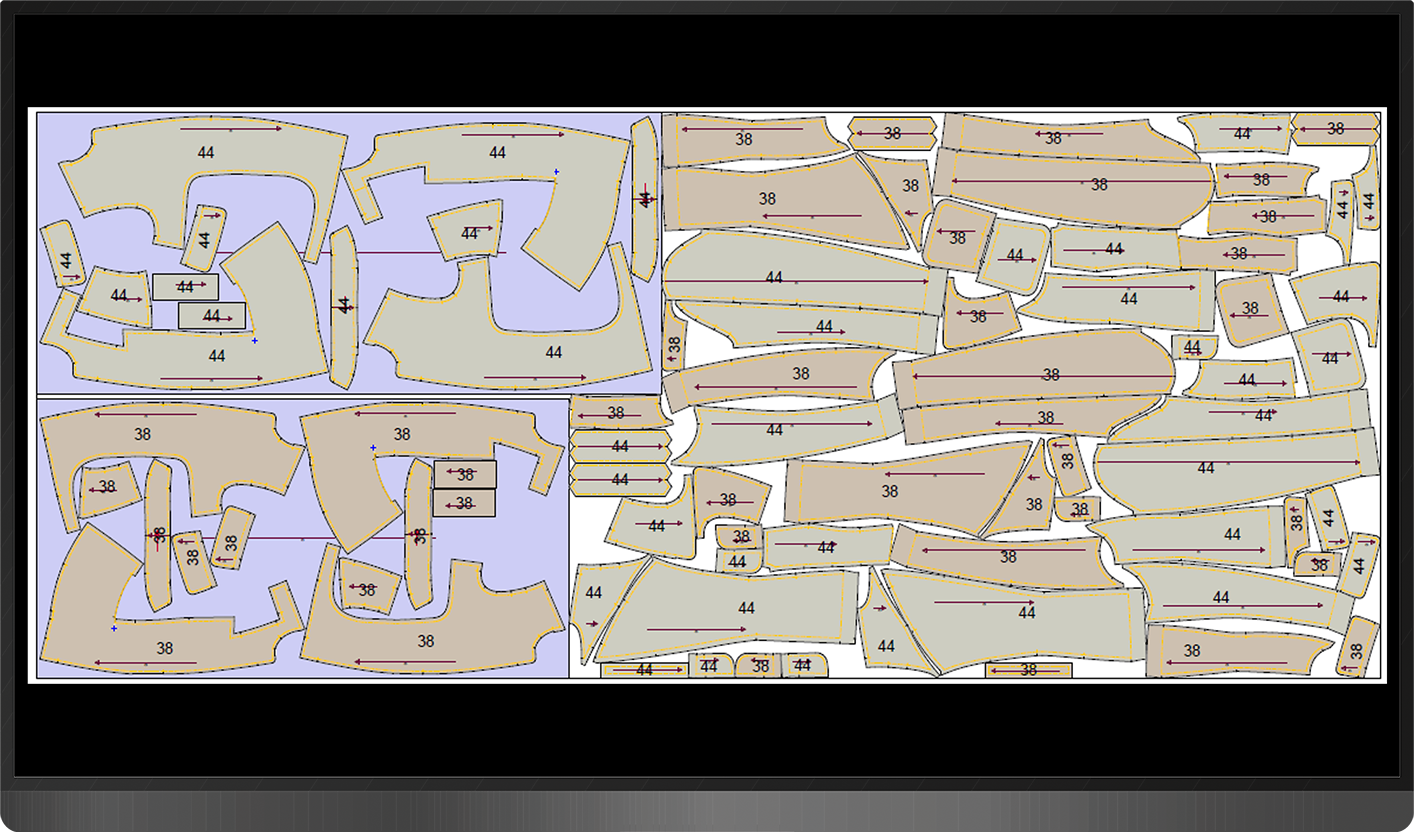

How Automarker works for you: from CAD to Cutter

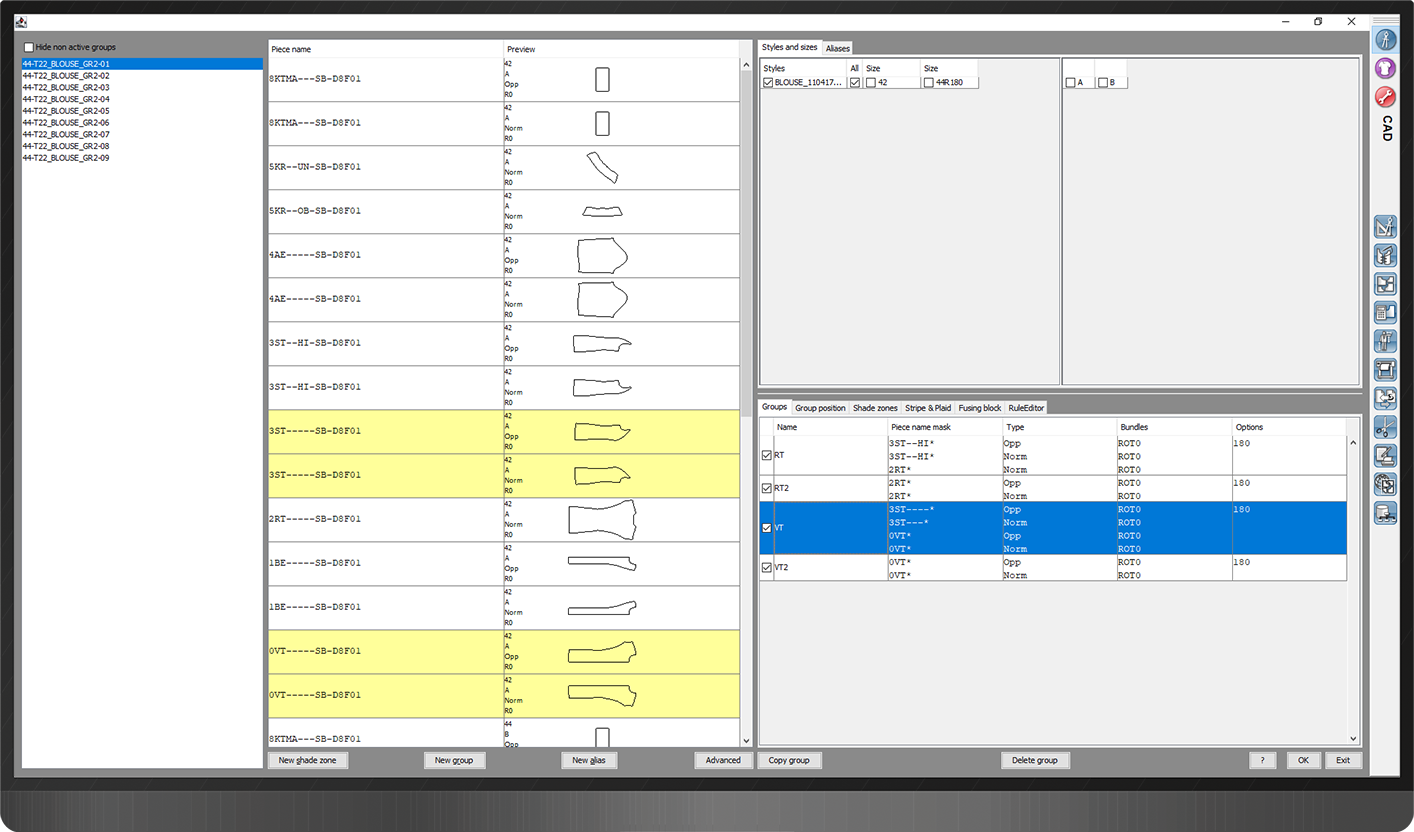

Start Automarker directly from your CAD software or upload your patterns to the secure Automarker cloud

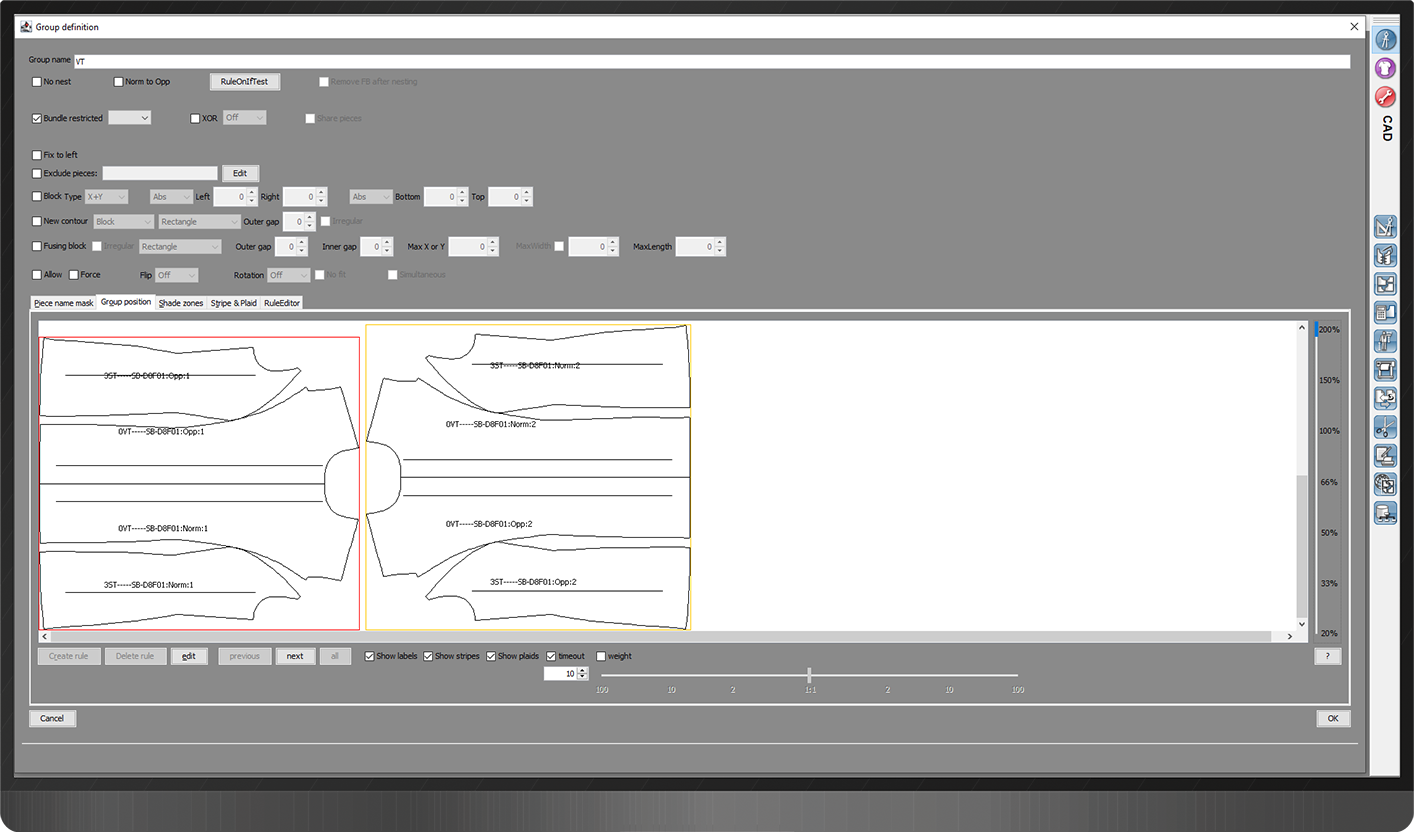

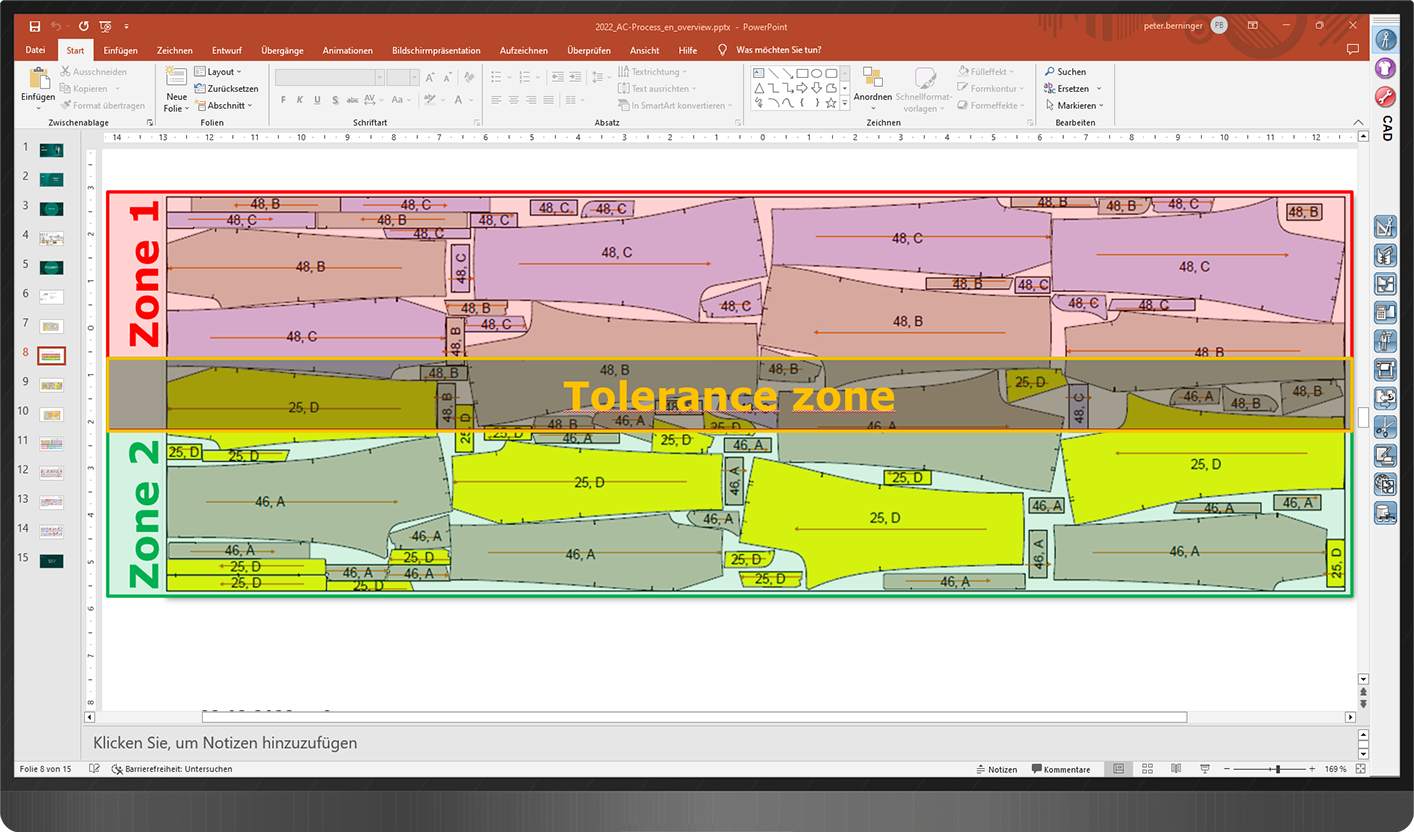

Automarker calculates pattern efficiency for different size combinations & shows the highest fabric utilization, considering material width, laying requirements, and individual settings.

The order is assembled automatically and, upon request, includes marker, plot, cut, and PDF files. Select the cut layout order and then send it via Automarker.

You can use common CAD data in Automarker and export the cut layouts in standard formats for plotters and cutters.

The big plus of Automarker

Ensure quality and know-how in your process

With Automarker, you can ensure the quality and efficiency of your process: The cutting patterns are directly selected from the Assyst.CAD database. Automarker ensures continuous data flow and automation up to the cutter/plotter. Even during peak times, you can deliver on schedule by defining precise quality requirements for each model and conveying your expert knowledge just in time to production partners worldwide, without any loss of information. This way, you can ensure quality even before cutting. This service is available worldwide, 24/7.

Optimal service quality and efficiency during peak times

The Rofa Fashion Group optimizes lead times in work preparation, material usage, and order communication across various locations using Automarker and Autocost. The result is perfect service and optimal quality despite a significant number of variations, for example, around 250 for a blazer per season.

How to get started with structured marker making

1

Register

2

Onboarding with the Assyst team

3

Support in Live operation