Assyst.Autocost

Cut Order Planning

With cut order planning software Autocost, you can calculate fabric consumption and production costs, optimize your orders, and ensure the profitability of your collections. Explore Assyst’s software as a service.

Working in a climate-friendly and profitable way

Autocost offers you many opportunities to work more sustainably while saving costs. For example, you can purchase only the necessary amount of fabric, easily coordinate orders with the same partner, and reduce transportation. Additionally, you can effectively ensure production quality.

Calculating costs & fabric consumption early on

With Autocost, you can use extensive data from planning and production, such as sales curves of mirror collections, size-weight ratios, material properties, and production environment, as a basis for accurate calculation of material requirements.

Secure price calculations and margins

Product prices are calculated long before fabric purchases. For this, reliable material and production costs are necessary. With Autocost and Automarker, you can calculate with realistic material usage and maintain quality, keep delivery commitments, and rely on the set profit margins.

Order optimization in the Cloud

automatically and always up-to-date

The financial benefits of using Autocost

With Autocost, you can optimize your savings potential. Outer fabric and ingredients (contrast fabric, lining, and interfacing) account for about 50-60% of the selling price. For example, at a turnover of €60,000,000, this corresponds to approximately €30,000,000. If it is possible to save only 1%, this would amount to at least €300,000. The investment in the service pays off after just a few production orders.

How to calculate costs and exact fabric consumption

Are you dealing with new collections or production orders? Start Autocost on the Automarker.com platform for cost certainty.

Forecast

Important data such as fabric items, costs, color, and orders, as well as sales numbers from the mirror season, are obtained directly from ERP, PLM, and PPS. Autocost provides the material requirements and costs in return.

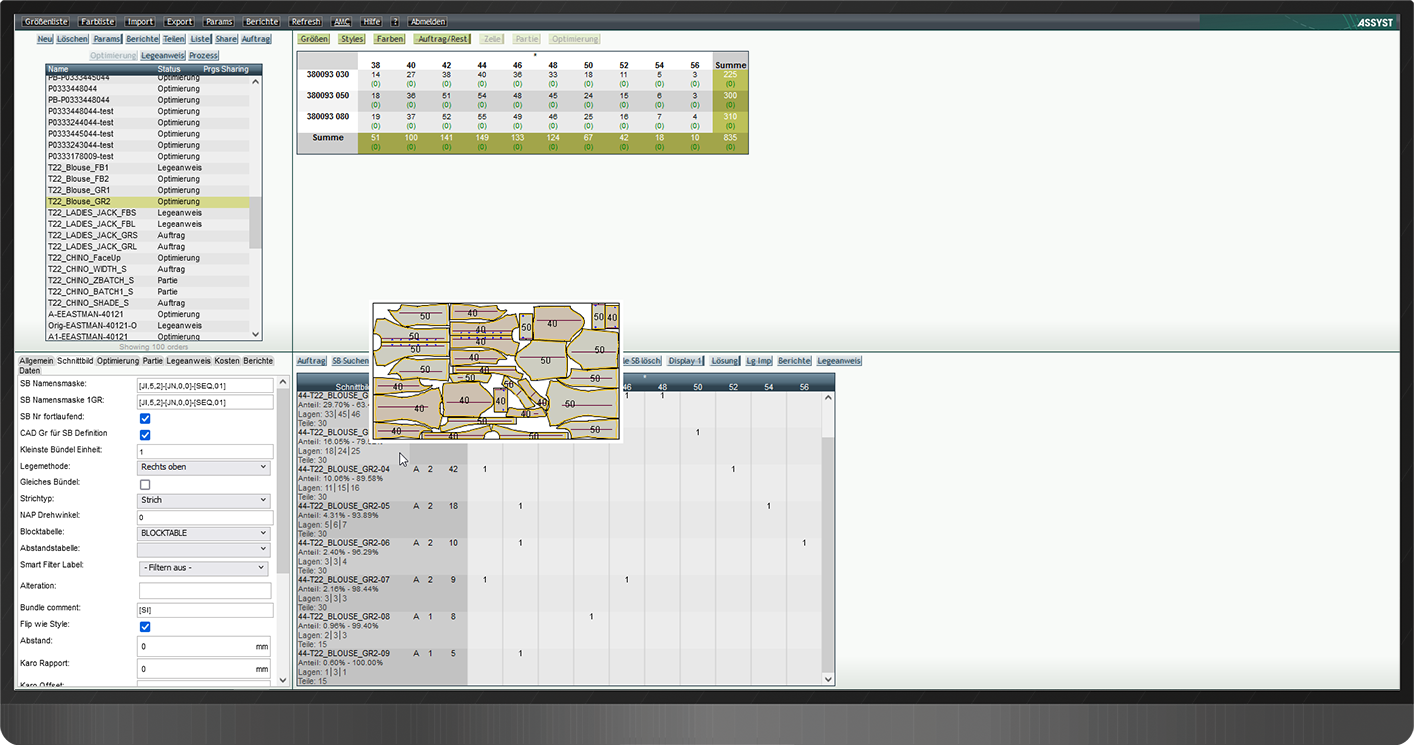

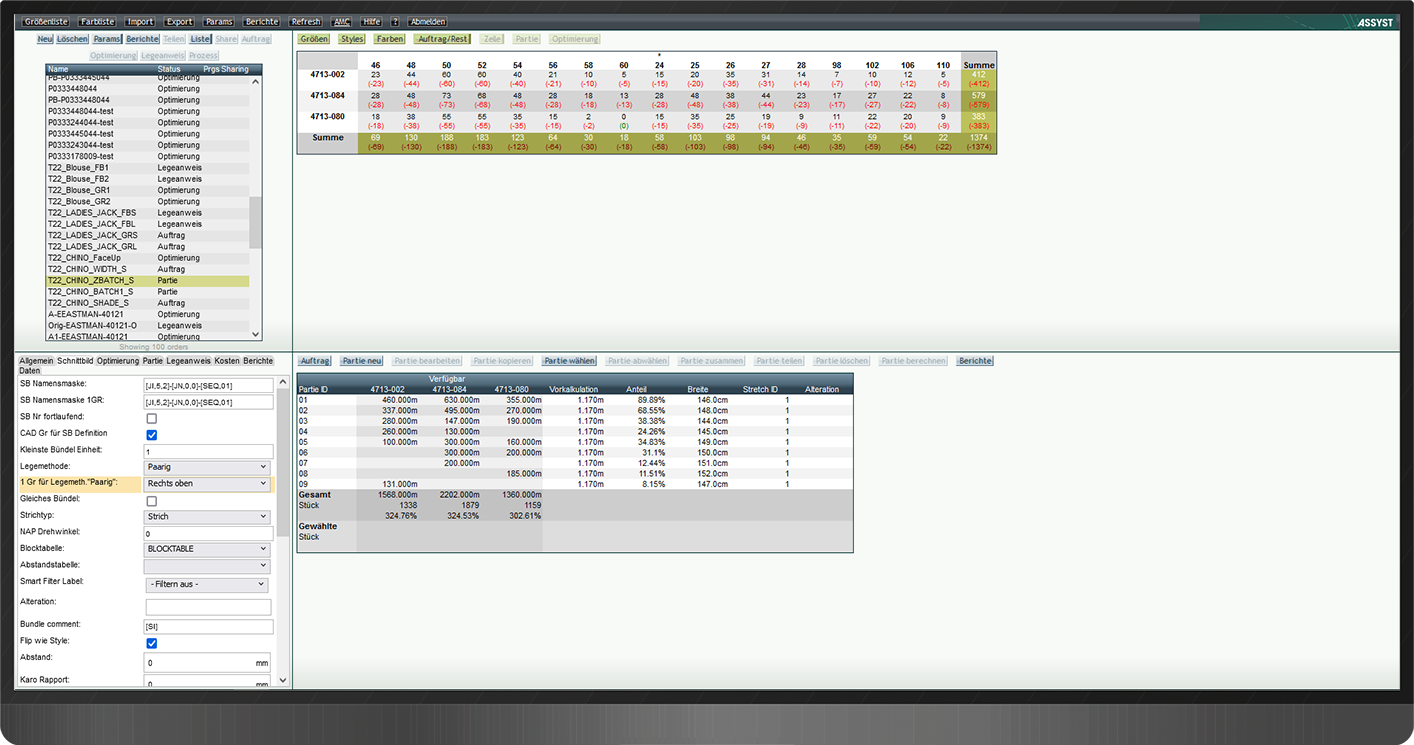

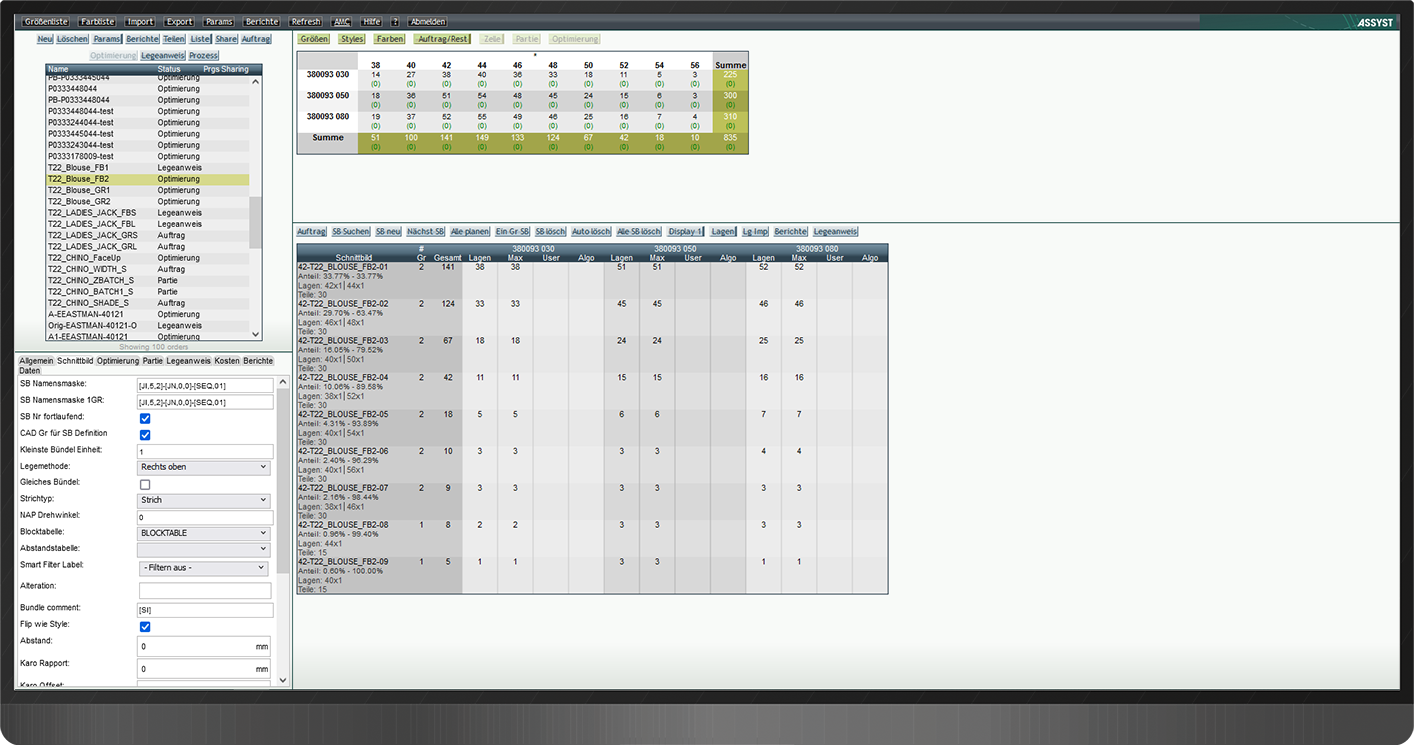

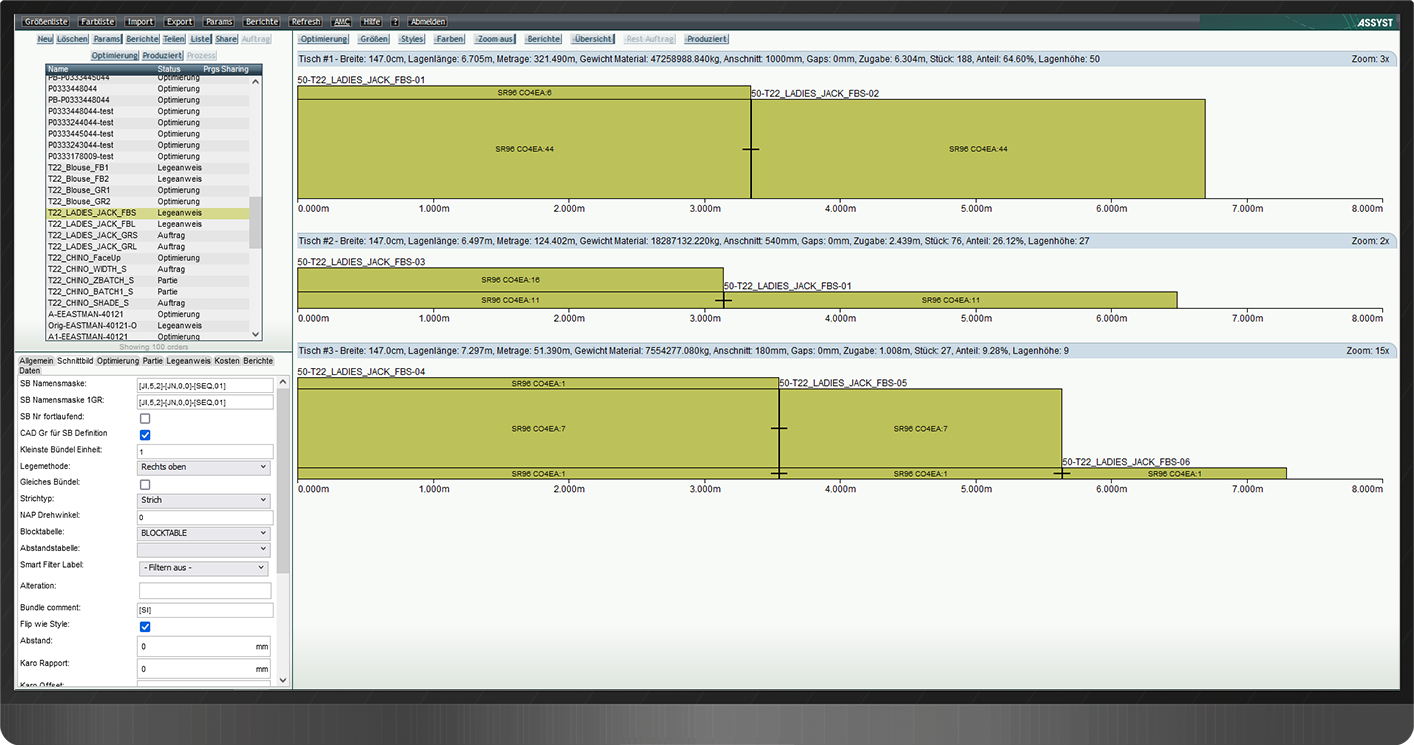

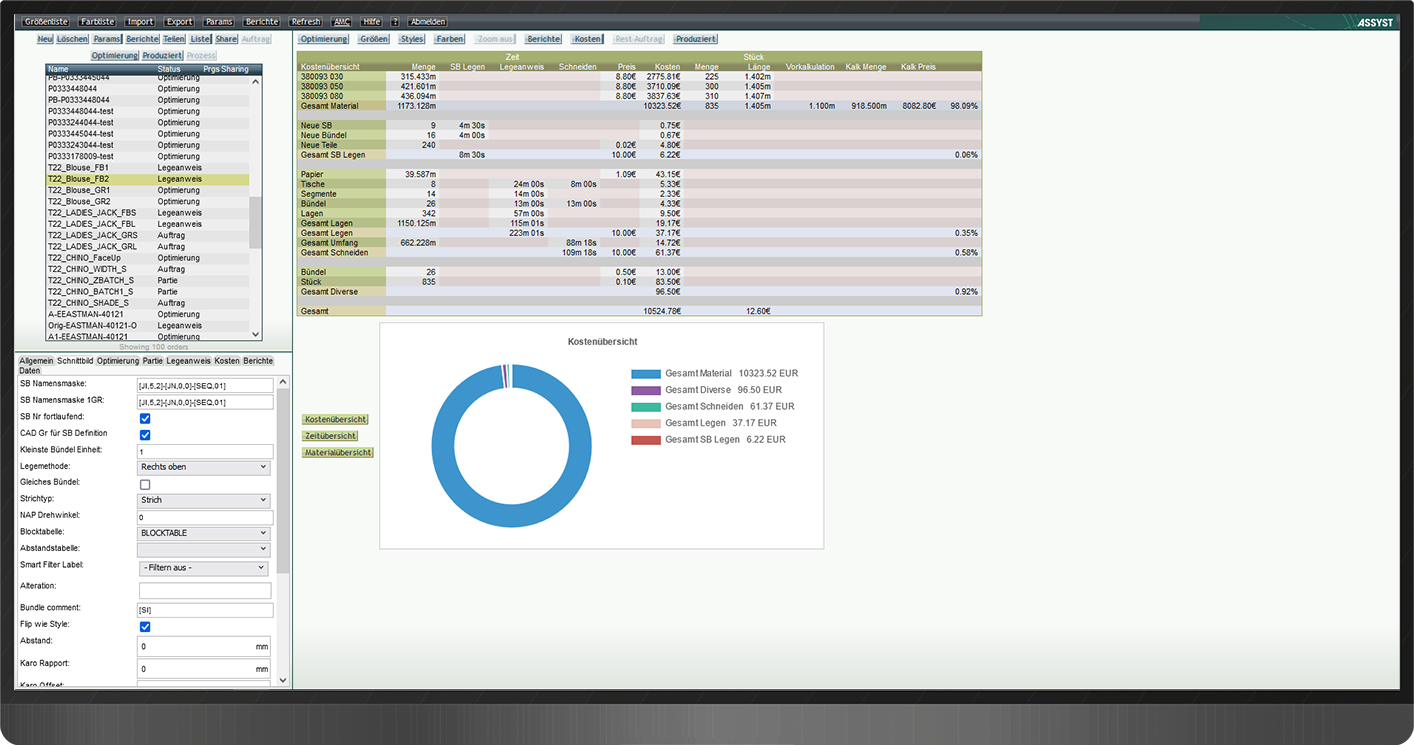

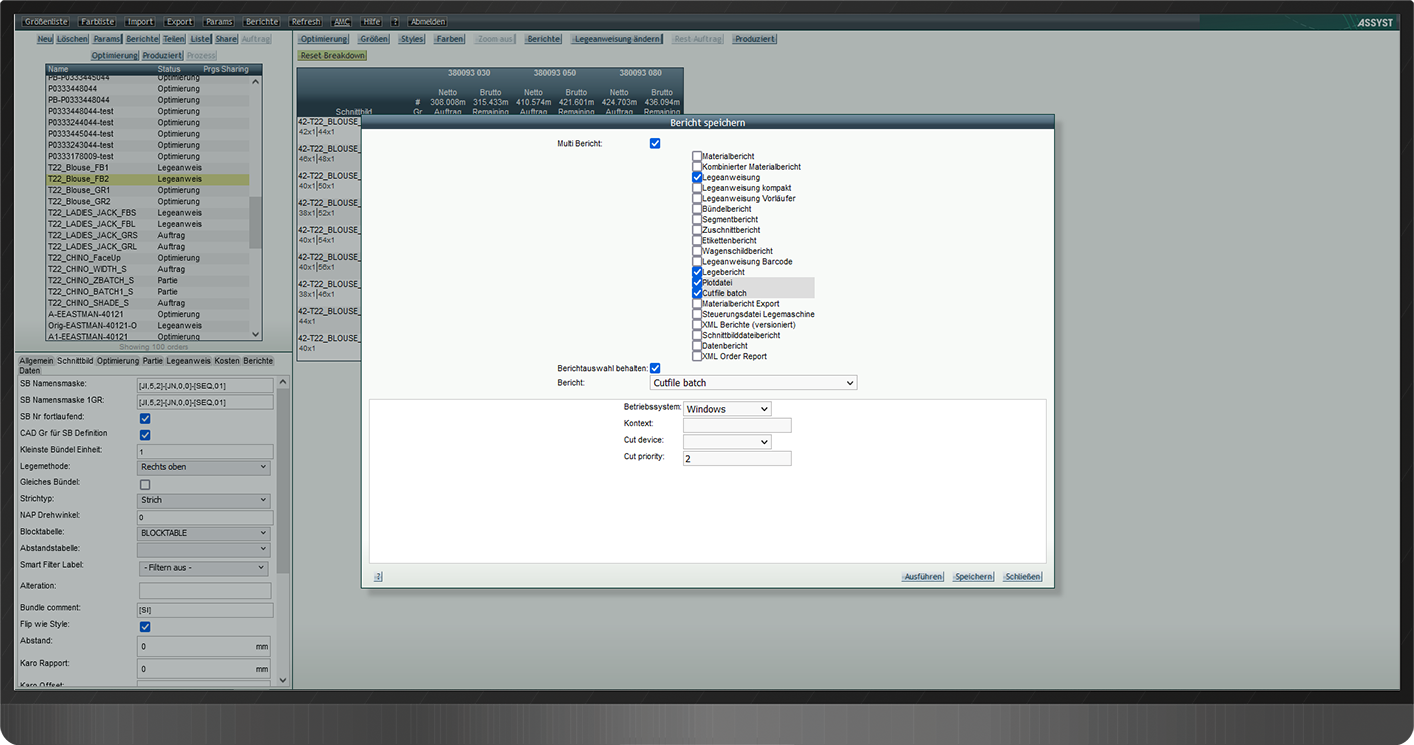

Detailed analysis

The costs and fabric consumption are determined for each model by size, material, and color, including the number of layers and the laying method. You can access detailed reports for material provisioning and production.

Make safe decisions

With Autocost, you can try out various lay scenarios. You can make informed decisions based on facts. All costs are transparent, and you can ensure the economic success of the collection.

The big plus of Autocost

The profitability and quality of the product must be ensured when creating an order, and often there is a lack of overview. With Autocost, you can quickly find the best solution and set the course for quality, cost, and fabric consumption. The system brings together information from pattern making, production, and order department and evaluates thousands of data and scenarios in seconds.

Smooth processes, cost savings, and quality assurance

“By using the Automarker.com platform, we are now able to determine the material requirements at an early stage of each model. This allows us to estimate the expected total material requirements early on and keep the associated costs in view. By optimizing orders through Autocost and the creators of the cutting patterns in Automarker, the calculated fabric consumption can also be maintained in production.”

Betty Barclay

Get easily started with transparent fabric consumption and optimized costs in the next collection.

1

Onboarding & training with the Assyst team

2

Integration into your IT landscape

3

Support during live operation